The process of placing boxes or products onto a pallet, while it may sound pretty simple, can be incredibly time consuming and a costly process in terms of worker compensation, not to mention the amount of physical stress it can cause to workers. Nowadays, automated palletizing systems are much quicker and more efficient than they were when they were first invented, so much so that there are a number of different systems to choose from based on your application and requirements. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

As an Authorized Systems Integrator for FANUC Robotics since 2000, Kaufman Engineered Systems applies FANUC robot technology to provide customers with turnkey end of line system solutions. Whether as simple as a single cell palletizing system, or as complex as a multi infeed build station — we’re prepared to match your requirements. No matter the task, we will treat your project with the same ...

More Automated Palletizing System Manufacturers

Specific types of automated palletizing systems were invented to coincide with certain applications, speeding up their process and adding more value to the overall process.

One type of design is the in-line palletizer which was invented to achieve the higher speeds that were coveted in the 1970s; this specific type of automated palletizing system is in constant motion and sorts the products before stacking them onto the pallet.

These palletizers are a step up from the row-forming palletizers that were popular in the 1950s, where their loads would be sorted into rows before being layered onto a pallet. Which brings us to the current state of palletizers, robotic palletizing systems.

These palletizers are able to take a product directly from the conveyor line and place them into an exact position onto a pallet. These robotic arms enable the system to pull products from varied elevations and place them in the most efficient manner onto a pallet, increasing the load stability of the pallet and adding value to the overall process by doing so quickly.

No matter what your application may be, you can be sure to find an automated palletizing system that is best for your application. The best way to do this is to reach out to experienced automated palletizing system manufacturers, explain your application and what you are looking for and they will be able to provide you with the best possible solution for your unique application.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

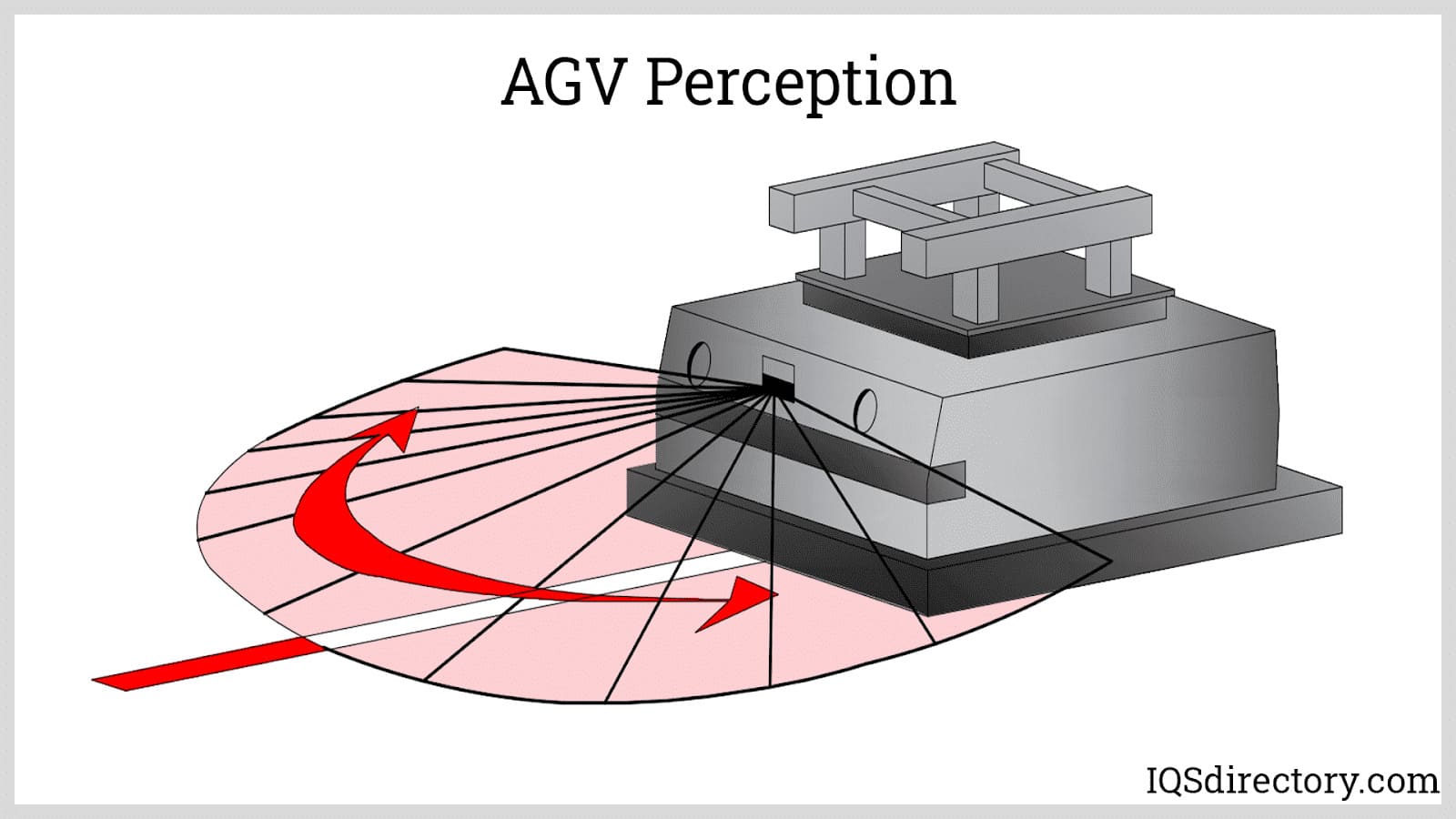

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Industrial Cranes

Industrial Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Industrial Heaters

Industrial Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches