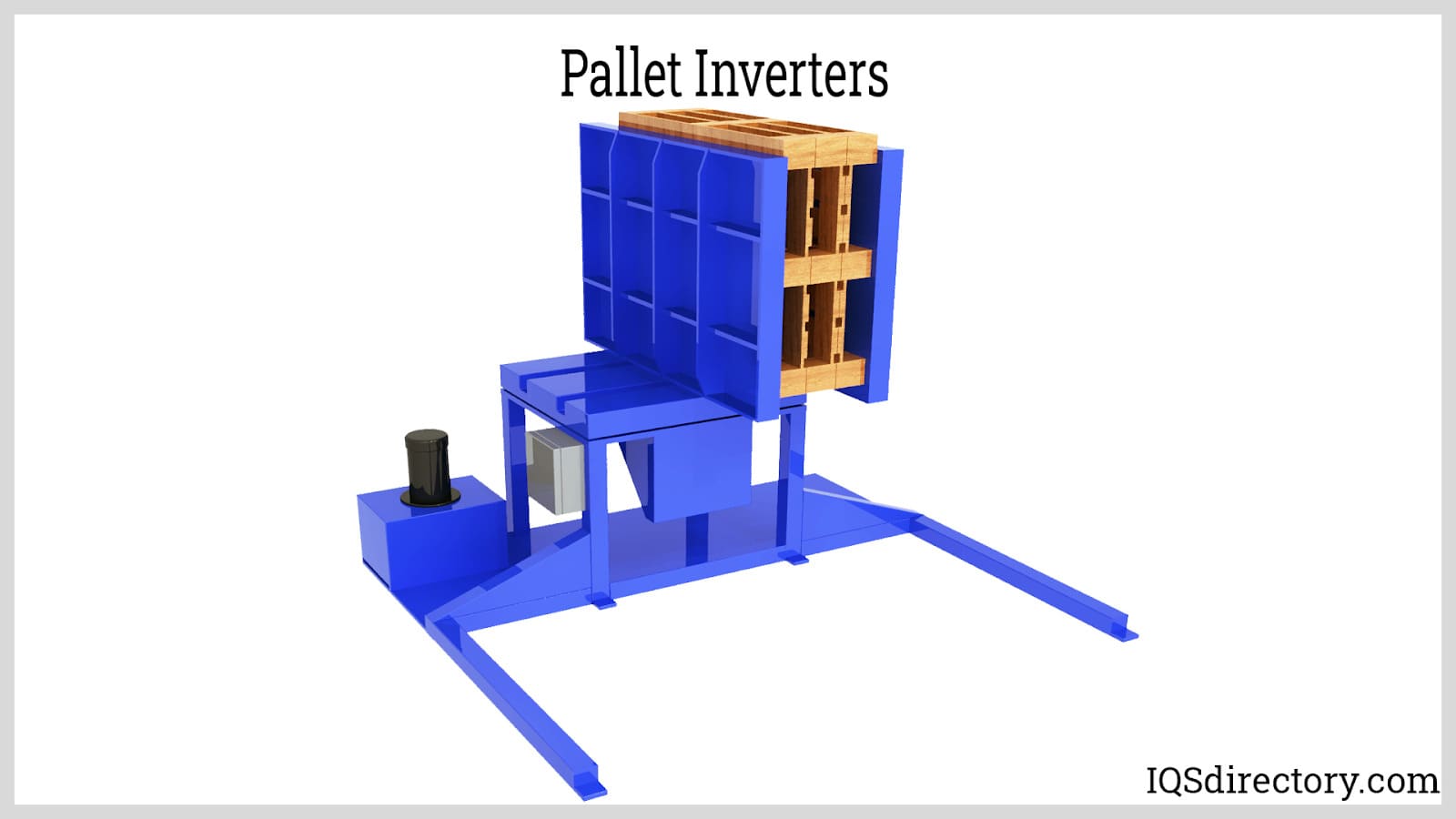

Pallet inverters allow pallets to be transferred, stacked in a warehouse, or moved to a shipping container, often independently. They are managed hydraulically by a driver of a vehicle resembling a forklift. Pallet inverters reduce the need to manually stack or transfer merchandise from one pallet to another. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

As an Authorized Systems Integrator for FANUC Robotics since 2000, Kaufman Engineered Systems applies FANUC robot technology to provide customers with turnkey end of line system solutions. Whether as simple as a single cell palletizing system, or as complex as a multi infeed build station — we’re prepared to match your requirements. No matter the task, we will treat your project with the same ...

More Pallet Inverter Manufacturers

Pallet inverters have become an essential material handling solution for a wide range of industries, including warehousing, distribution, logistics, manufacturing, food processing, pharmaceuticals, and more. Businesses widely utilize pallet inverters because they provide safe, efficient, and reliable means of rotating, exchanging, or transferring palletized loads. By automating the pallet exchange process, pallet inverters significantly reduce the risk of workplace injuries associated with manual material handling, such as lifting or repositioning heavy loads. This also helps minimize product damage, ensuring goods remain intact and uncontaminated during transfer.

In traditional pallet handling, employees would have to physically lift or move products from one pallet to another, exposing them to ergonomic risks and increasing the likelihood of damaged goods. Modern pallet inverter machines revolutionize this process by using mechanical or hydraulic systems to rotate entire pallet loads, making the transfer seamless and consistent. The latest generation of pallet inverters can be integrated into automated warehouse systems, featuring remote controls, programmable logic controllers (PLCs), and conveyor integration for continuous operation. Many advanced models, such as fully-automated pallet changers, can handle high-throughput operations, automatically transferring loads from one pallet to another and depositing them at the end of a conveyor line with minimal human intervention.

Whether you operate a small warehouse or a large-scale distribution center, investing in a pallet inverter system can deliver substantial improvements in productivity, safety, and operational efficiency. Read on to explore the types, working principles, applications, benefits, and key decision factors for choosing the right pallet inverter for your facility.

Types of Pallet Inverters

Pallet inverters come in a range of designs and configurations to suit different operational requirements, load types, and facility layouts. Understanding the various types of pallet inverters is crucial for selecting the optimal solution for your needs.

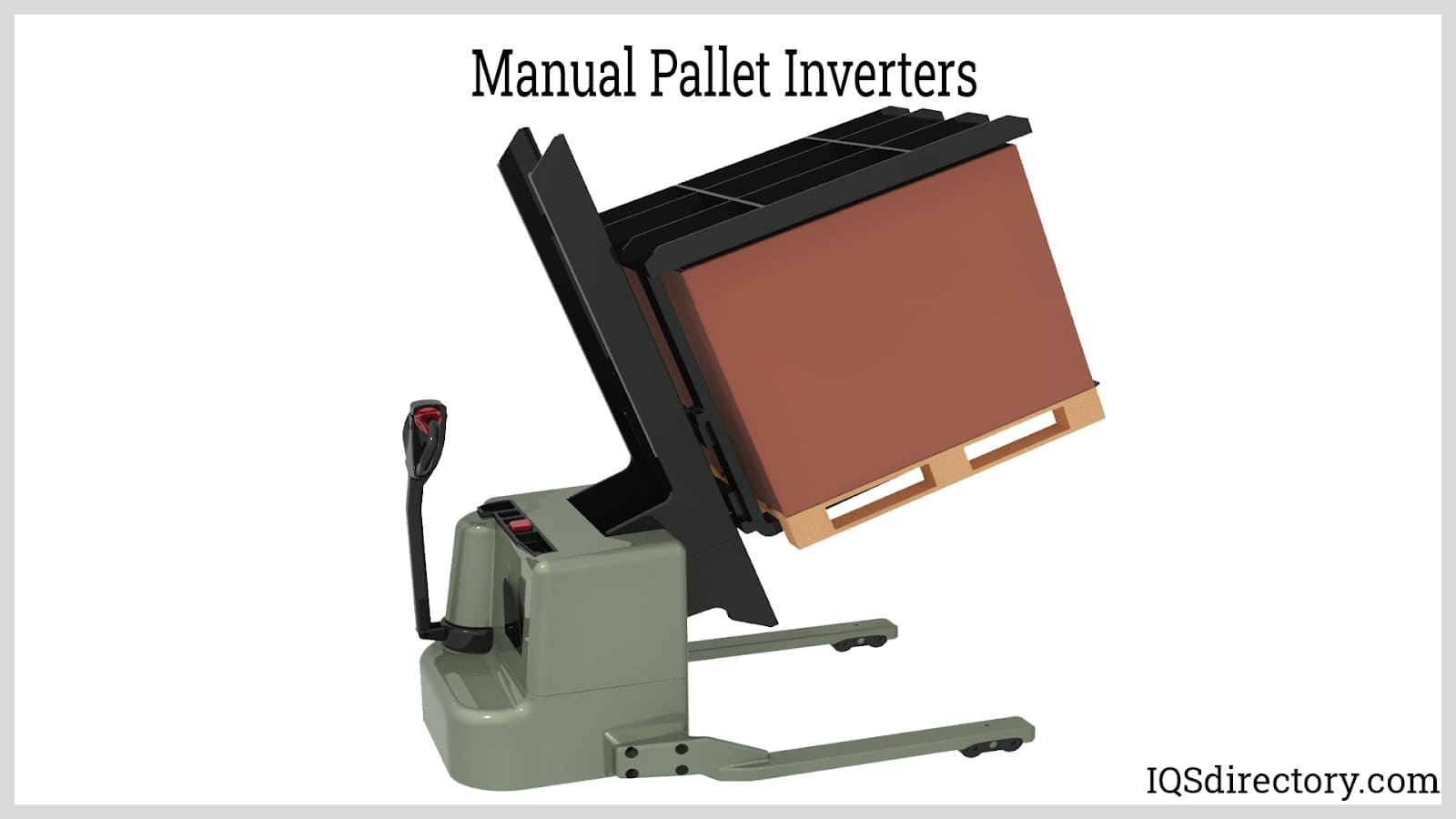

- Manual Pallet Inverters:

Manual pallet inverters are ideal for small warehouses, workshops, or facilities that handle lower volumes of palletized goods. These units are generally operated by a lever or hand crank, providing a simple and cost-effective way to rotate or exchange pallets without requiring electrical power. While manual models offer lower throughput, they are compact, portable, and easy to maintain, making them suitable for operations where flexibility and budget are primary considerations.

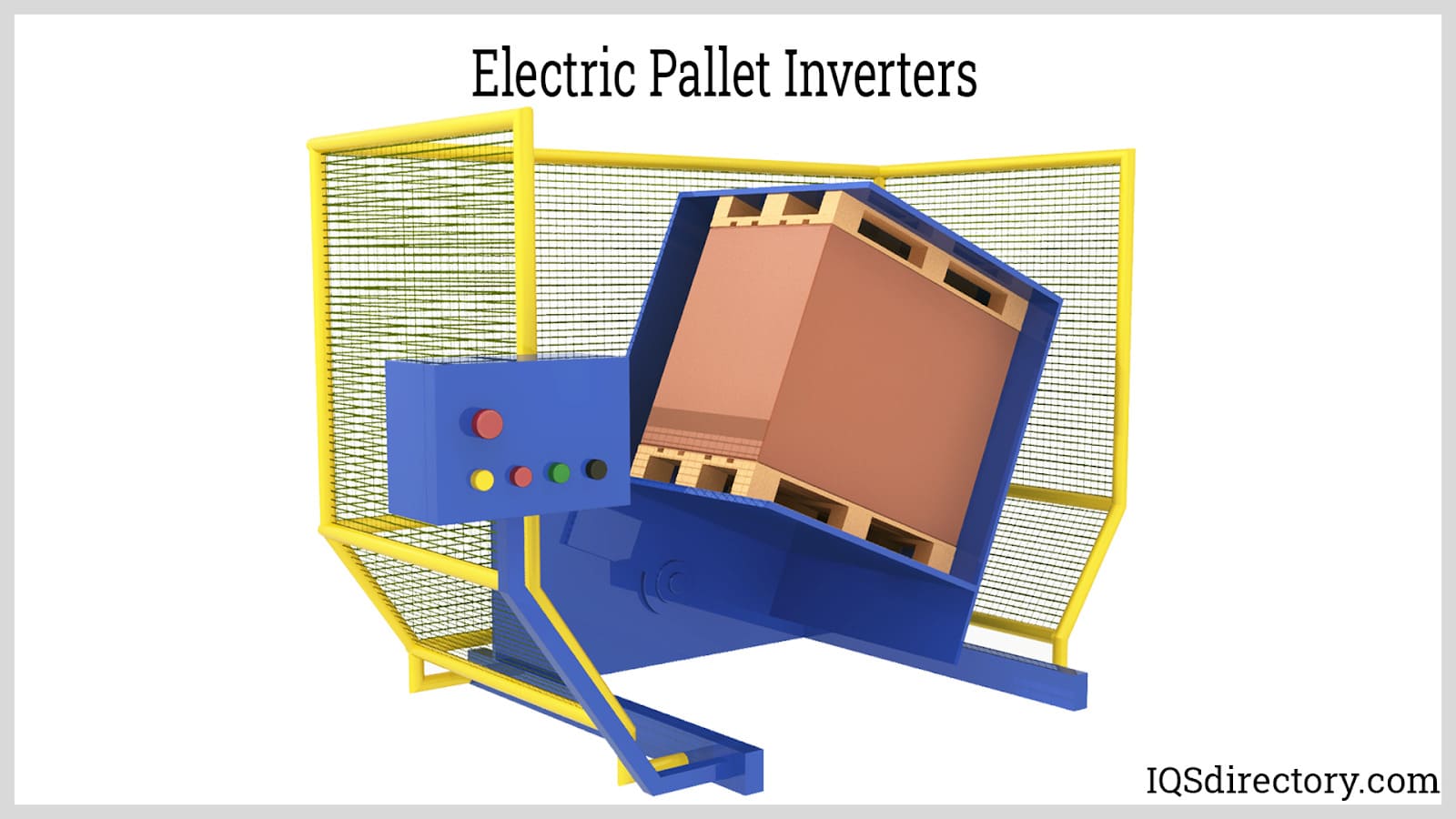

- Electric Pallet Inverters:

Electric pallet inverters are widely used in large warehouses, distribution centers, and manufacturing plants that require higher levels of automation and throughput. Powered by electric motors, these inverters can handle multiple pallets simultaneously and are often integrated into conveyor lines or automated storage and retrieval systems (AS/RS). Features such as push-button controls, safety interlocks, and programmable cycle times enhance both productivity and operator safety. If you need to minimize manual intervention and maximize process efficiency, electric pallet inverters offer an excellent return on investment.

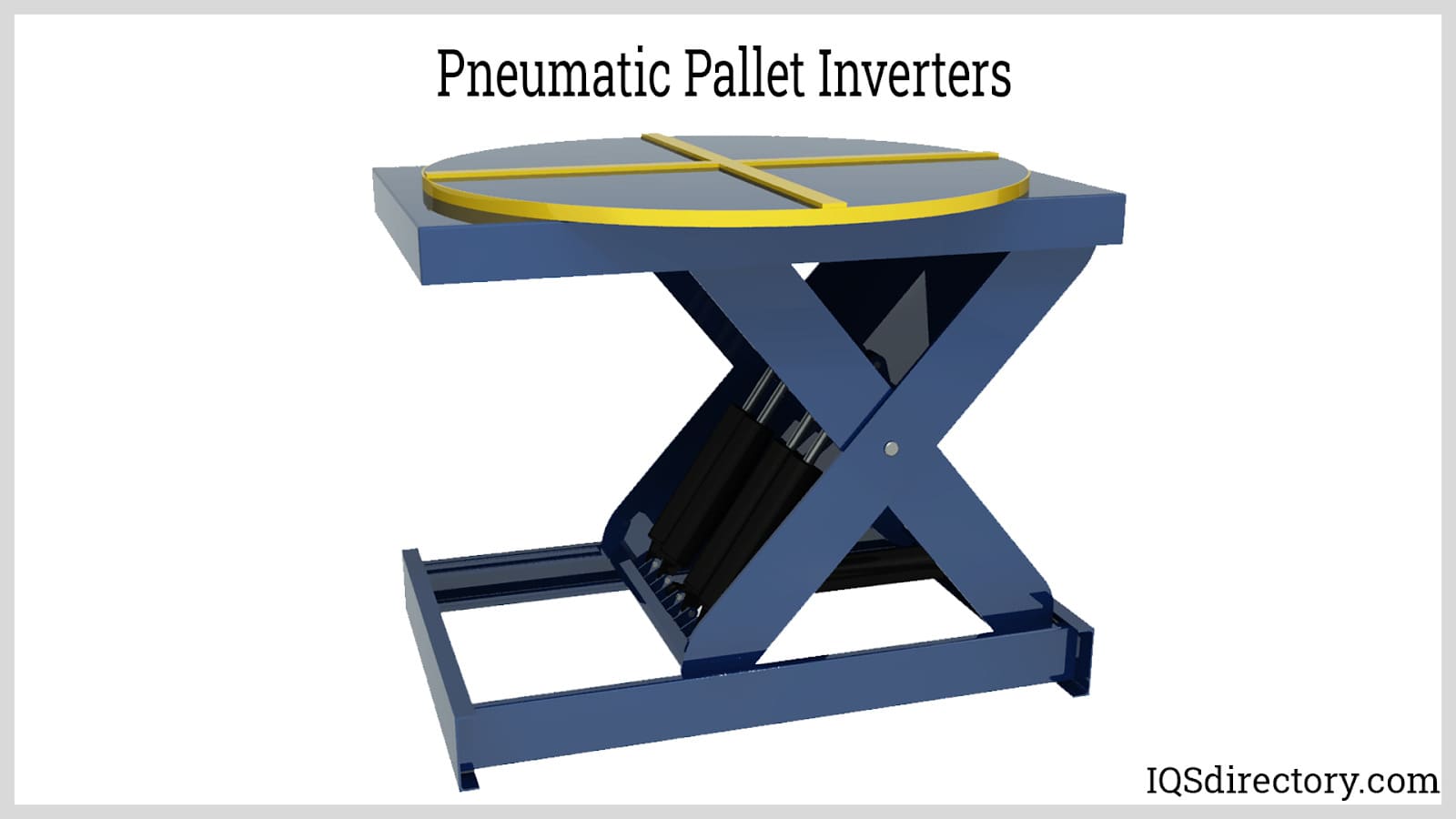

- Pneumatic Pallet Inverters:

Pneumatic pallet inverters utilize compressed air to power their rotation and clamping mechanisms. Often found in large-scale industrial environments, these models are preferred when electrical equipment may pose a risk (such as in explosive or wet environments) or when air-powered machinery is standard within the facility. Pneumatic inverters deliver high-speed operation, robust performance, and can be configured for fully automated pallet transfer processes, making them suitable for applications demanding rigorous cleanliness or safety standards.

What Items Can Be Handled by Pallet Inverters?

Pallet inverters are engineered to accommodate a broad spectrum of load types, materials, and packaging formats. Their versatility makes them indispensable in sectors where product integrity, hygiene, and operational speed are paramount. Common items and materials handled by pallet inverters include:

- Aluminum or plastic pallets: Frequently used in cleanroom environments or food and pharmaceutical industries where sanitation and contamination control are critical.

- Products utilizing internal pallet racking: Items stored on specialized racking systems that require regular pallet exchange or rotation.

- Pallets with unique dimensions or sector-specific designs: Custom-sized pallets designed to meet the needs of automotive, electronics, or aerospace industries.

- Traditional wooden pallets: Standardized for manufacturing, storage, and shipping; may require transfer to hygienic or export-compliant pallets.

- Slip sheets and lightweight pallets: Used to reduce shipping weight and lower transportation costs.

- Freezer spacers and sling bags: Essential for efficient handling of frozen goods and bulk materials.

- Cartons, drums, or bulk bags: Pallet inverters can rotate or exchange various packaging types, safeguarding against damage or contamination.

Looking for a specific pallet inverter for your industry? Explore our supplier directory to compare models designed for unique material handling challenges.

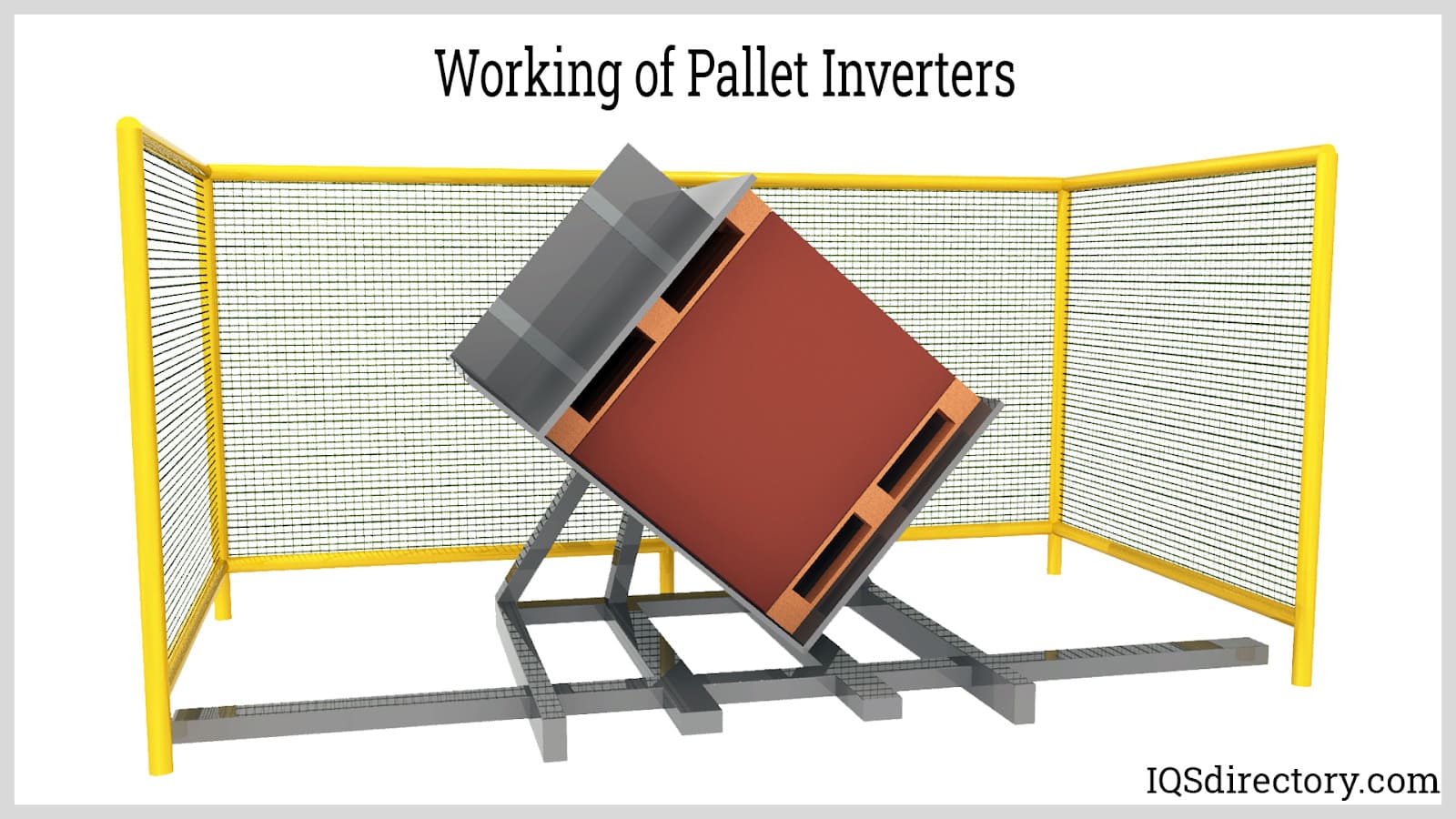

How Do Pallet Inverters Work?

The working principle of a pallet inverter is based on secure clamping, controlled rotation, and gentle release of palletized loads. Here’s a typical step-by-step workflow for an automated pallet inverter system:

- The product load is placed onto the feed conveyor or directly into the pallet inverter’s loading area.

- The inverter’s control system (manual, electric, or pneumatic) activates the feed conveyor (if present), moving the palletized load into position. Integrated safety sensors detect the load to initiate the next step.

- Hydraulic or pneumatic clamping arms gently but firmly secure the load, ensuring it remains stable and undamaged during inversion.

- The machine rotates the entire clamped load—commonly up to 180 degrees—allowing for safe transfer, replacement, or inspection of the pallet or goods. The inverter can also be programmed for partial rotations as needed.

- After rotation, the clamping arms release, and the load exits the inverter, either manually or via a discharge conveyor.

- Many advanced units feature programmable settings for speed, rotation angle, and clamping pressure to optimize for different load types and applications.

- Optional safety features include emergency stop buttons, light curtains, and interlocked gates to protect operators.

Key Benefits of Using Pallet Inverters

Investing in a pallet inverter can deliver measurable advantages across material handling operations. Consider these top benefits when evaluating pallet inverter solutions for your warehouse, factory, or logistics hub:

- Bulk handling efficiency: Move entire loads, not just individual boxes, improving throughput and reducing labor costs.

- Versatility and adaptability: Swap between different pallet types (wood, plastic, aluminum) without the need for extra equipment, accommodating changing customer or regulatory requirements.

- Load straightening: Inverters can correct misaligned or inclined loads, improving stability and safety for stacking and transportation.

- Specialized functionality: Many pallet inverters can be customized for unique tasks, such as handling fragile goods, frozen products, or bulk bags.

- Reduced product damage: Automated inversion minimizes manual contact, decreasing the risk of drops, crush damage, or contamination.

- Enhanced stacking and storage: More efficient and uniform stacking, especially compared to forklifts, enables better use of warehouse space and reduces the risk of mishaps.

- Improved ergonomics and safety: Eliminate the need for manual lifting or re-stacking, reducing strain and workplace injuries.

- Process integration: Pallet inverters can operate as standalone units or be integrated directly into automated production lines or conveyor systems.

- Optimized handling of frozen or sensitive goods: Easily access freezer spacers or flip products to prevent settling, ensuring high product quality.

- Faster pallet exchange and reduced downtime: Streamline the entire pallet transfer process, keeping your operations agile and responsive.

Curious how a pallet inverter could streamline your specific workflow? Contact a pallet inverter supplier to discuss custom applications and ROI calculations.

Common Applications of Pallet Inverters

Pallet inverters are utilized in virtually every sector where palletized goods are handled, stored, or shipped. Typical industries and applications include:

- Pharmaceuticals and food processing: Maintain hygiene by transferring products from wooden or external pallets to sterile, cleanroom-compliant or in-house pallets.

- Warehousing and logistics: Exchange expensive internal pallets for lower-cost shipping pallets, or replace damaged pallets quickly without unpacking goods.

- Manufacturing: Remove defective or unwanted items, correct misaligned loads, or facilitate product inspection and quality control.

- Chemical and hazardous materials: Prevent cross-contamination by segregating loads and quickly replacing pallets exposed to spills.

- Frozen food and cold storage: Rapidly access freezer spacers and rotate large quantities of frozen goods for efficient handling and transport.

- Export and import compliance: Switch to ISPM 15-compliant pallets for international shipping, or remove non-compliant materials before customs inspection.

- Automotive and electronics: Handle specialized parts and components on custom or anti-static pallets, improving process reliability.

- Retail and distribution: Speed up cross-docking operations, reduce labor, and ensure products arrive in optimal condition.

Need help selecting the best pallet inverter for your industry? Use our interactive guide to compare models and features, or request a customized quote today.

Decision Factors When Selecting a Pallet Inverter

Choosing the right pallet inverter requires careful evaluation of your operational requirements, facility constraints, and long-term business goals. Here are the main factors to consider when researching, comparing, and investing in a pallet inverter system:

- Load capacity: Determine the maximum and minimum weight and size of your typical palletized loads. Most standard inverters handle up to 4,400 pounds, but heavy-duty models are available for larger loads.

- Pallet and product types: Consider the range of pallet materials (wood, plastic, metal) and product packaging (cartons, drums, bags) your operation handles.

- Level of automation: Decide if a manual, semi-automated, or fully automated inverter best aligns with your throughput and labor goals.

- Footprint and integration: Assess available space in your facility and whether the inverter needs to be mobile, stationary, or integrated with existing conveyor or racking systems.

- Safety features: Look for units with robust safety controls, such as emergency stops, light curtains, and interlocked gates, especially in high-traffic environments.

- Ease of use and maintenance: Opt for intuitive controls, quick-change features, and readily available spare parts to minimize downtime and training requirements.

- Compliance and hygiene: Ensure the inverter meets industry-specific standards for food safety, pharmaceutical GMP, or export regulations if applicable.

- Return on investment (ROI): Calculate the payback period by factoring in labor savings, reduced product damage, and increased throughput.

- Supplier reputation and support: Choose a supplier with a proven track record, comprehensive support, and customization options.

Want expert advice on choosing the right pallet inverter? Browse our supplier directory and compare leading brands, or contact us for personalized recommendations.

How to Choose the Correct Pallet Inverter Supplier

To achieve the best results when investing in a pallet inverter, it's vital to select a supplier that understands your industry, application requirements, and operational goals. Our comprehensive directory of pallet inverter suppliers makes it easy to research, compare, and connect with top-rated manufacturers and distributors.

- Research suppliers: Use our directory to explore each supplier’s business profile, areas of experience, product range, and customer support capabilities.

- Review company websites: Take advantage of our proprietary website previewer to quickly assess what each company specializes in and the solutions they offer.

- Request quotes and information: Use our simple RFQ (Request for Quote) form to contact multiple pallet inverter companies simultaneously. Provide details about your application, load characteristics, and project goals to receive tailored recommendations.

- Compare and evaluate: Analyze proposals based on features, pricing, lead times, warranty, service, and reputation. Don’t hesitate to request references or case studies from similar industries.

- Finalize your decision: Work collaboratively with your chosen supplier to ensure the selected pallet inverter meets your facility’s needs, complies with regulations, and delivers long-term value.

Ready to start your search? Visit our pallet inverter supplier directory now, or submit an RFQ to connect with leading manufacturers and distributors.

Frequently Asked Questions About Pallet Inverters

- What is a pallet inverter and how does it work? A pallet inverter is a material handling device that securely holds and rotates entire palletized loads, allowing efficient transfer, replacement, or inspection of pallets without manual unloading.

- Which industries benefit most from pallet inverters? Warehousing, logistics, food processing, pharmaceuticals, chemical manufacturing, cold storage, and export/import operations all gain efficiency, safety, and compliance advantages from pallet inverter use.

- Can pallet inverters handle fragile or sensitive products? Yes, many modern pallet inverters feature programmable clamping pressure and gentle rotation to safely handle fragile, sensitive, or high-value goods.

- How do I determine the correct pallet inverter for my operation? Consider your load sizes, types of pallets, frequency of pallet exchange, desired level of automation, safety requirements, and facility layout. Consult with suppliers for site-specific advice.

- Are there mobile or portable pallet inverter options? Yes, several models are designed for mobility, allowing you to move the inverter between workstations as needed for flexible operations.

- What safety features should I look for in a pallet inverter? Look for emergency stop switches, enclosure guards, light curtains, interlocks, and compliance with OSHA, ANSI, or CE standards.

- Can pallet inverters be integrated with existing automation systems? Absolutely. Many advanced models offer PLC integration, conveyor compatibility, and remote operation for seamless automation.

Enhance Your Material Handling Operations with the Right Pallet Inverter

Selecting and implementing the right pallet inverter can dramatically increase the safety, productivity, and profitability of your warehouse, distribution center, or manufacturing facility. By automating pallet transfer, reducing manual labor, and protecting goods, pallet inverters have become indispensable across a multitude of industries. Whether you require a compact manual unit, a fully integrated automated system, or a custom-engineered solution, there is a pallet inverter designed for your unique operational needs.

Take the next step: Browse our directory of leading pallet inverter suppliers to compare models, request quotes, and discover how top businesses have optimized their material handling processes with state-of-the-art pallet inverter technology.

Still have questions? Contact our experts for personalized support, or explore our Resource Center for in-depth guides, case studies, and industry insights on pallet inverters and advanced material handling solutions.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

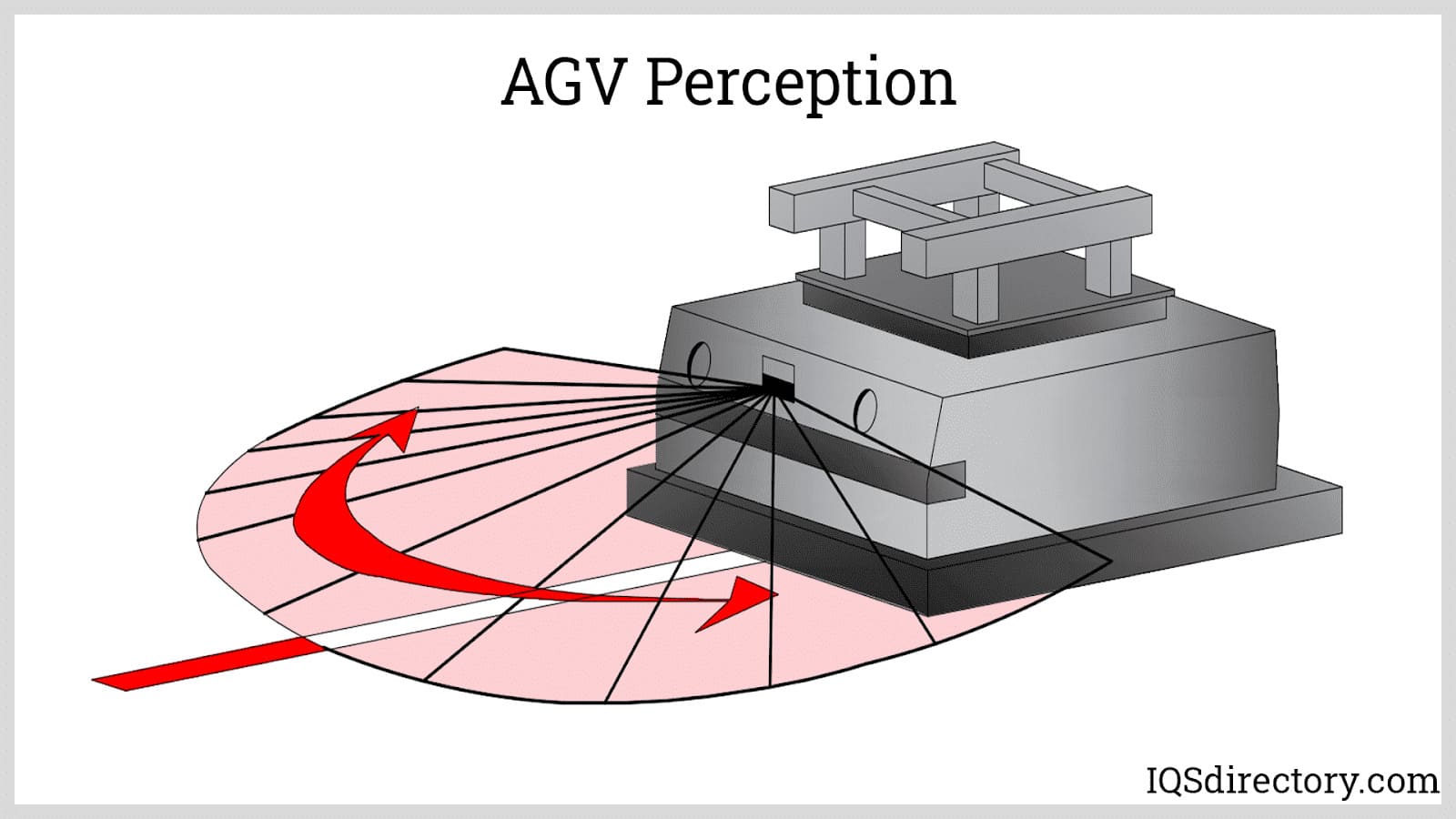

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Industrial Cranes

Industrial Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Industrial Heaters

Industrial Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches